Some time ago I was contacted by Intercon srl, a company from Piacenza area, that produces different types of cosmetics at retail, wholesale and also for third parties. A medium-sized reality that is facing like many other Italian companies the transition to Industry 4.0, digitizing several monitoring processes and making metrics accessible-in this case-to the management software they use.

The point of this post is to summarize the project made and installed for the Technical Office (the very kind Francesco Puglielli) in the factory. It has been a while since I have been back in a factory. A post I wanted to do for Christmas, and of course it comes out at Easter 🤦♂️

The Project

I am asked to identify and install several sensors to monitor various data, such as

- Temperature and humidity in two departments

- Fill level of two tanks (one placed vertically, one horizontally)

- The amount of liquid (I think water) in two meters placed in two very distant places inside the factory, one outside and one inside

The data must be collected locally and sent to the management system adopted by the company: Rilheva, a company also based in Piacenza, a powerful and resilient product. Immediately we interfaced with Rilheva staff who turn out to be extremely helpful and also interested in the project.

It had been years since I had found people so open. Unfortunately, here in Italy, realities are not always permeable to other realities that offer new solutions. I take this pretext to thank them.

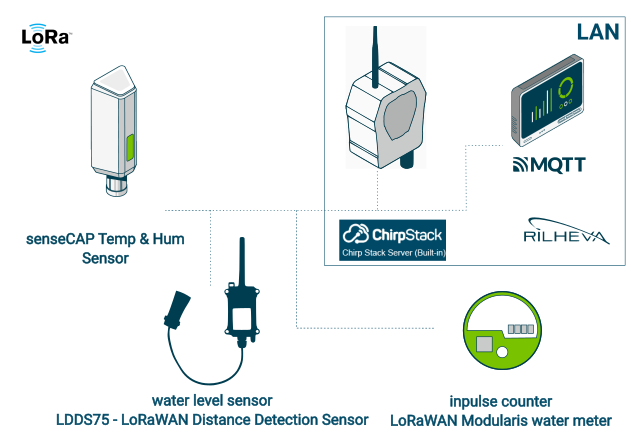

Here I have made a small graphic that summarizes the piece we added to Intercon’s system. The most interesting part being the use of the ChirpStack server, which is hosted inside the SenseCap Gateway per esterni a 868 MHZ.

The server is listening to SenseCap Temperature and humidity sensor, LDDS75 di Dragino Distance Sensor (I’m asking myself here: is the “-ino” in Dragino for Arduino?), and the Prince of the sensors used here, the Modularis CM3022 di NAS.

Space dedicated to my students: –> There are several realities at play here, certainly Seeedstudio that I related with to understand some parts of the process of initializing the Chirpstack Server on the Gateway. Then ChirpStack itself, because the way I’m using this server involves using a local MQTT broker. The data coming in has to be manipulated in real time, and that does not happen, and will not happen for a while (ecumenical in Mr. Chirpstack's words) in Chirpstack. So, with respect to Rilheva Management (Example of writing payload : {"id":@ID, "val":@VALUE, "ts":@TIMESTAMP} ) This piece now occurs in the ReTerminal to which I have succumbed to, that natively host Node-RED. A product too nice not to leave on the Engineering Office table, small touch dashboard on which to analyze data in real time and send it to Rilheva. The only device to log in remotely. The NAS pulse counter is wonderful. The NAS team is staying in one of the most beautiful places in the world I have been in my life: on the island of Sarema, Their office I imagine is not far from Kaali Crater. I had some problems initially integrating the sensor and they even gave me the honor of a call. Thanks to them as well. Always closing for my students: such a project needs a thousand analyses, questions. Do not be afraid of those who will answer that you ask stupid questions. It happens to me all the time and on a daily basis.

Project finished and delivered, only a little maintenance in January 2024 for fine-tuning. Keep you updated or ask for info somehow if you are interested or curious.